Does Bioengineering Hold the Key to Our Material Future?

The race to create the next biggest fibre is on, and in fact, has been for the last decade. There are those that stand on the line of using what is in existence and the age-old techniques and processes our ancestors developed, and there are those that like to be in a lab creating solutions to amaze and wow potential investors.

In this article, we take a look at six developments in the field of bioengineered fibres, and what the pros and cons can be in terms of sustainability and ethics.

Bolt Threads

This "spider silk" manufacturer hs replicated the proteins from spider-spun silk in order to create a yarn - MicroSilk - that has the high tensile strength and durability of silk, but without using any wildlife. Using bioengineering techniques, the "genes" are put into yeast that is then fermented at scale using sugar and water. It is then spun in a similar process to rayon and acrylic. While it has been used to create the Stella McCartney x MOMA Gold Dress below, and some commercially-available products like a tie and knitted beanie hat, it is unclear what additional inputs the fibre needs to become a yarn i.e. chemicals like with rayon filament production.

Pro: a great alternative for vegans, though a touch more expensive and less attainable at the moment. Their main draw is that it offers performance and sustainability - what is not understandable is why ethically-produced silk underperforms in characteristics and animal or environmental harm.

Con: still very little information on the full production inputs due to the hush hush nature of fibre development. They say sugar is the main input, but this has to take up arable cropland that can be used for food. With natural silk production, the worms are in trees that are capturing and storing carbon, providing shade down below and retaining moisture in the soil.

Werewool

Another "biodegradable" fibre made not from a natural raw source, Werewool is developed by a team of materials scientists and alumni from the Fashion Institute of Technology’s Textile Development and Marketing course. They have a bunch of awards, and a bunch of FAQs on their site, but very little translatable information - as is the case with all in-development textiles.

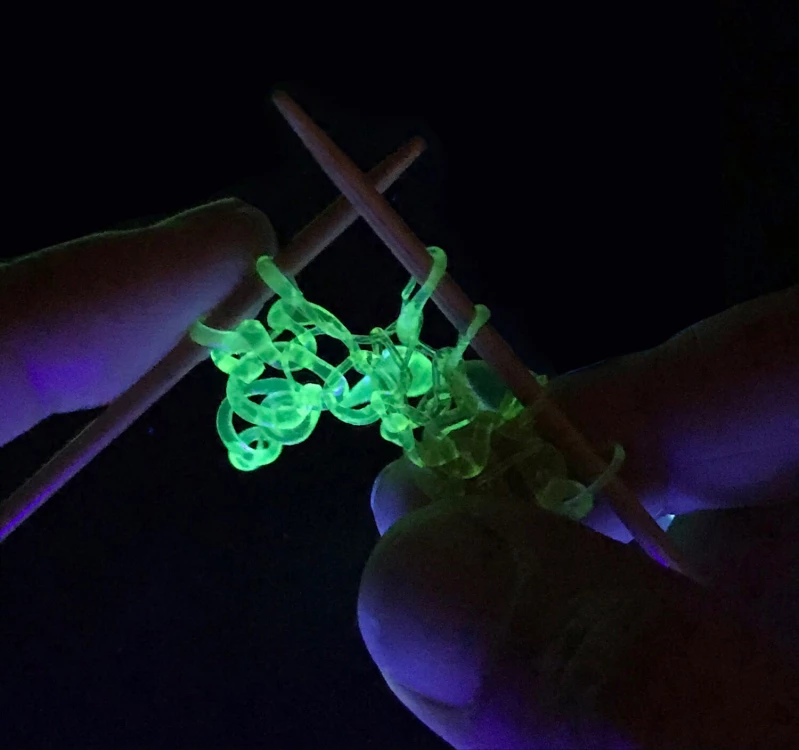

Pro: it is said to be a naturally elastic, fluoroescent fibre due to the protein structure, so if nothing else, it could potentially be used in activewear and sportswear.

Con: why do fibres need to be created in a lab for them to be called circular? We have an abundance of raw material that is literally burned because there is not a demand for it.

@SustainableFCo talks about the impact of bioengineering materials on ethics and sustainability.

Post Carbon Lab

Another site with very little information, Post Carbon Lab have touted their approach to research and development as "regenerative sustainability activism" - almost like a What Three Words placefinder. At least here the research does have a tangible solution, in that they have considered already how clothing with a photosynthetic coating could have effects in drawing down carbon from the atmosphere. The aim is to make sustainable fashion accessible to everyone just by putting on everyday garments.

They have also looked at bacterial pigment dyeing, which is really cool (though images have been removed). It looked at creating colour in labs through utilising natural pigments in bacteria.

Pro: speculative design gives you avenues for solutions that you may not get just by working in the normal method. It can be a strain to get excited about something that seems a long way off, but every innovation starts from this discussion and play.

Con: another long way off research project with little achievable action in the short or long term for brands and consumers.

Brewed Protein

This not-wool from Japan-based companies Goldwin and Spiber is, like MicroSilk above, made from bioengineered genes and spun into a yarn like wool. So far, they have created a small amount of knitted jumpers that were accessible via a lottery in certain countries - but, the jumper was made with 70% sheep's wool anyway because little Brewed Protein yarn currently exists. Spiber was building a factory in Thailand to be able to scale up the production.

Ultimately, the companies envision the material beginning to replace fossil-based materials like polyester, while it also provides a lower-impact alternative to materials like cotton, which requires large amounts of water, or wool, which comes with the environmental footprint of raising sheep. ~ Fast Company

Pro: genuinely, there isn't one, unless you are vegan and really want to fight for both not wearing an animal product and not wearing synthetics. They at least showcase on their site the academic papers that have investigated the molecular structure and physical properties of "spider silk", so if you like your fibres with science over substance, there you go.

Con: We have bundles of waste wool that can be processed into beautiful knitted pieces. We can breed sheep that have finer wool. And we can wear what is already in existence. It is farcical to say that sheep have a larger environmental footprint than a factory without showing evidence.

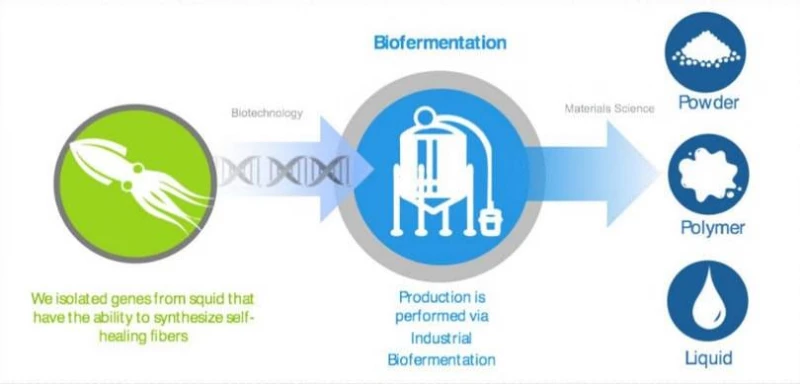

Tandem Repeat

Squid genes have been investigated and found to possess self-healing characteristics. For this reason, research company Tandem Repeat have researched the bioengineering of a fibre from the protein of squid genes. The applications would for instance prevent the shedding of microplastics through offering a coating. Their so-called "SRT" coating does not break down after abrasion tests, and so also has applications for biomedical implants or garments tailored for protection against chemical and biological warfare agents. This goes much deeper than just fashion, and though it is a hefty website, if you so care to delve into the research that has been undertaken, you will find a lot.

Pro: applications are vast and it feels like there is a real-world solution other than just making some cool clothing. Actual smart materials.

Con: it's still taking the genes of an animal for our own gain.

Huue

Huue (previously Tinctorium) is a biotechnology company making indigo dyes in a lab from bacteria. Instead of using toxic chemicals, the Huue team turn sugar into dye. From first examining how colour compounds occur in nature, they "leveraged proprietary bioengineering" (existing tech and machinery?) to create microbes that mirror nature’s process to consume sugar that will enzymatically produce dye. We recommend listening to the podcast episode on Spirit Of 608 'Reinventing Indigo' that best explains the idea process and technical stuff.

Pro: it doesn't require vast land, humid climates and the scaling of chemicals to produce dye for our many jeans.

Con: it still requires vat amounts of sugar, energy for the machinery and it is not yet commercially scalable (the limited website shows that).

Read more on the pros and cons in this article from Minnpost 'Using biotech to made indigo-dyed denim a bit more green'.

If you would like to receive sustainable and ethical textile and fashion news to your inbox on a weekly basis, join as a Member of The Sustainable Fashion Collective.