What are the benefits of using 3D Printing in Fashion?

Imagine you have an event with nothing to wear. Forget panic shopping – you simply calmly open your computer and download a digital file for a cute dress. After loading up your 3D printer, you send the file and it prints your dress to your exact measurements (all within a few hours).

Sounds too good to be true? There are quite a few innovations bringing us closer to 3D printed apparel being an everyday occurance. Plus, many large and small brands are incorporating this waste-free technology into their manufacturing. Not only would 3D printing have great benefits for both consumers and brands, but it has impressive potential in terms of sustainability.

In this article by guest author Laurice Wardini, dive into the future of 3D printing.

3D printing could help reduce (or even completely eliminate) many negative environmental aspects of the fashion industry...

- 11.1 million tons of textiles were thrown into landfills in 2017

- On average, textiles take 200+ years to break down in landfills

- Textiles emit methane while they break down (a harmful greenhouse gas)

- In regular tailoring methods, 15% – 30% of fabric is wasted

- On average, 2,700 liters of water are required to produce one cotton t-shirt

- An estimated 20% of overall water pollution comes from the textile industry

- Fast fashion factories cause damage to nearby communities (i.e. polluting drinking water and damaging ecosystems)

How could 3D printing help?

It eliminates waste and could use materials that are less water intensive than cotton (as well as other natural and synthetic fabrics). The material used would typically be recyclable and easily reusable, helping reduce the amount of clothing thrown into landfills. Additionally, at-home printers can help reduce the impact of large factories.

Benefits for Brands

Small batch sizes – Eliminate the need to wait weeks (or even months) for inventory shipments from overseas.

Quicker to market – Typically, new brands have to go through quite a rigorous process before they’re ready to start shipping orders. 3D printing can help make this a much quicker and easier process (easier to create samples, no need to wait weeks for inventory shipments, etc.)

Customisation – 3D printing allows for much easier customisation (such as specially tailored sizing).

Quick printing – Out of stock? No longer a problem. Print your garment in under 24 hours (many startup 3D printing brands create the garment after you place your order).

Minimal inventory – On a similar note, brands can eliminate the need to purchase huge orders of inventory and could keep a minimal amount of products on-hand.

Improved fabrics – Fabrics are in production that will be more breathable and easier to move around in (plus, no wrinkles).

Recyclable clothing – 3D printed apparel will likely be much easier to recycle and reuse than current materials.

Big Brands Currently Using 3D Printing

Although it might sound like a fantasy, there are quite a few large brands already utilising 3D printing.

Nike – Created the first 3D printed upper, plus they are already using the technology in smaller components [read more on the Flyprint here]

Adidas – Designing 3D printed midsoles

New Balance – Created the first mass-produced 3D printed midsoles

NASA – Experimenting with 3D printed chainmail to protect astronauts

Victoria’s Secret – Using the technology in lingerie runway shows

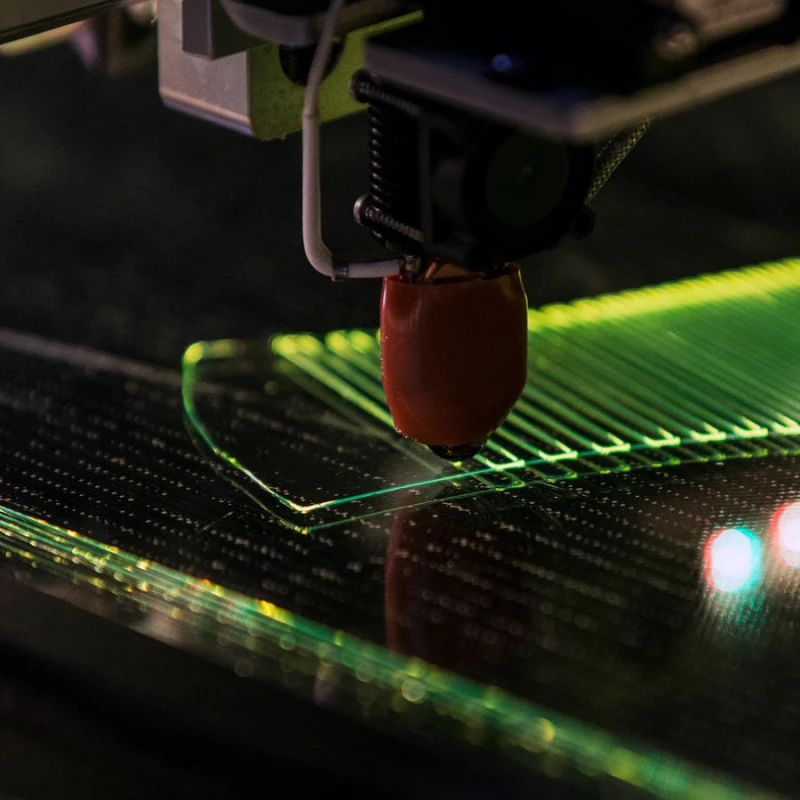

Nike's Flyprint uppers on the printer ready to be sewn up

Innovative Designers + Brands

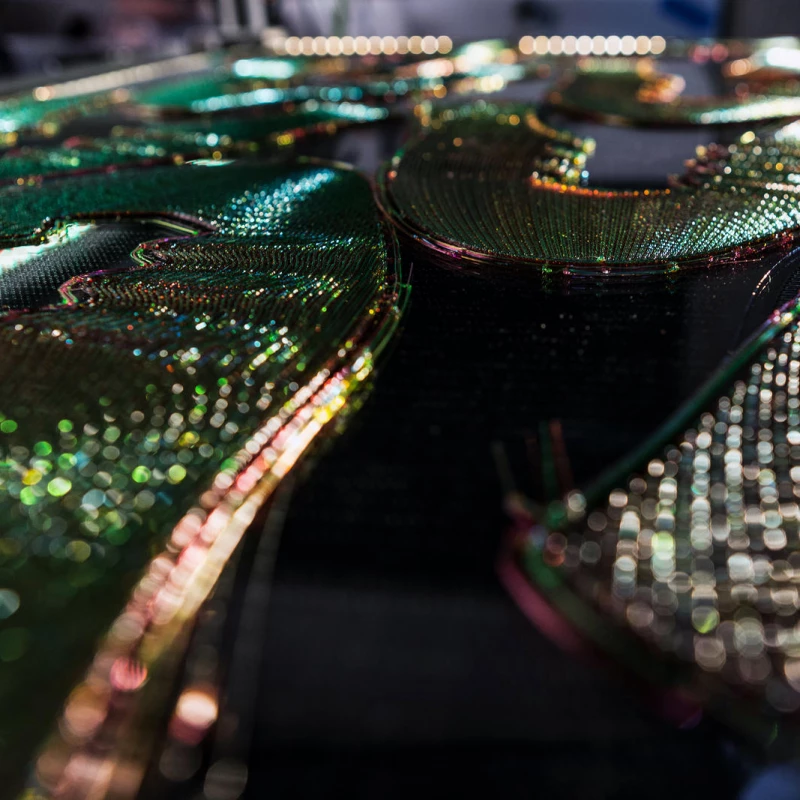

Danit Peleg – Created the world’s first purchasable 3D printed fashion collection in 2015, all from her own home. She also has an online course to teach the world about using this technology

Julia Daviy – Designs commercially available clothes and bags made using 3D printing

Sylvia Heisel – Designs purchasable, custom, made to order 3D printed coats ($12,000) and dresses ($4,000) that can also be composted [read more on that project here]

Ice & Kostika – This startup brand shows that, despite the current fabric restrictions, incredible wearable products can be created using 3D printing. Although their shoes look like something of the future, you can purchase them now ($500 – $5,500 per pair)

Ministry of Supply – Uses a more affordable combination of 3D printing and 3D knitting in their business wear, resulting in 35% less waste ($45 – $300 per item)

Close ups of Danit Peleg's flexible 3D printed clothing

3D Knitting vs 3D Printing

Another innovative technology that’s becoming more widely used is 3D knitting. These similar terms often get confused, but 3D printing and 3D knitting are two different things.

3D Knitting

This technology essentially automates the regular knitting process. While industrial knitting machines have been around for decades, newer digital machines allow you to send files for it to automatically knit. Previously, such machines were expensive and primarily used by large companies. However, new companies (such as Kniterate) are working to bring the technology into everyday households. This will help reduce waste.

While 3D knitting helps minimise waste and bring production into homes, it still requires the use of fabrics that impact the environment. That said, 3D knitting is currently more accessible than 3D printing and allows for easier, less expensive customized clothing that minimises waste. Many brands are currently utilising 3D knitting to help reduce waste.

3D Printing

These machines work by heating up certain materials, then forming objects layer-by-layer. Most current materials are various forms of plastic or metal.

The Future of 3D Printed Fashion

Smart clothes - Intel and other tech brands have created prototype smart clothing with 3D printing (incorporating technology like mood sensors, color-changing features, attention span trackers, etc.)

Download & Print Clothes At Home - Danit Peleg and other industry experts believe we’re moving towards a future where we will print our own digital clothing files from home with ease.

The lack of flexible and comfortable material is the only current roadblock to using 3D printing in everyday clothes. It will be much more widely used once such materials are created (many innovators are working on this, with frequent improvements).

Regardless, the technology is being used for many other purposes. You can find 3D printing in futuristic runway styles, costume design, furniture, everyday accessories, and even by big brands for small components (such as shoe brands and leather brands).

Written and information sourced by Laurice Wardini, the founder of ClothedUp @officialclothedup

Tune in to this podcast episode from Vogue Business on how 3D tech can transform the fashion design process, and this article on how made to order business models are exploding due to the innovations in fashion tech. You can also learn more about 3D Printing and troubleshoot common issues here.