Fabrics From Food Waste, Mushroom And Weeds

The UN's Sustainable Development Goal 2: Zero Hunger, looks at ending hunger, achieve food security and improved nutrition, and promote sustainable agriculture. There are organisations that are building practices to reach these targets. So in our Masterclass on this topic, we spoke to a range of experts to learn about fashion’s impact on food sources, crop health, farming communities and local processing plants, alternative regenerative fibres for fashion fabrics, and the ways designers can support regenerative agriculture practices and a traceable leather industry.

One aspect of this is producing textiles from food, growing textile crops alongside food crops, and utilising byproducts from the agricultural sector. In this article we take a look at some of the talked about "food fibres" on the market today, and their pros and cons when it comes to sustainability and ethics.

Innovations

Algiknit

Durable yet degradable yarns are being developed from kelp, a food source that is recently being used more and more as a sustainable solution to our fixation on plastic. Seaweed is regenerative, in that it naturally grows, so as long as the forests are managed well, this can be an abundant resource.

Pro: abundant, readily available resource requiring limited inputs and does not need land.

Con: there will always be organisations that exploit and over-produce, so managing seaweed as the live being it is would need to come from a place of respect for the wider picture.

Milkweed

A readily-occurring "weed", wild milkweed was collected in the US around World War 2 as the fibres were known to aid buoyancy in life vests. Alayna Rasile and Charlotte Sullivan headed up May West, a materials research lab in North America, though in 2020 stopped development. The brand used the milkweed as a down alternative. Fortunately there is still a textile company investigating the holistic uses of milkweed - Faborg. Based in India, Shankar and team have created a wool alternative using the calotropis plant. As May West discovered, milkweed is loved by butterflies, but other acts of regeneration also come from the leftover stems during processing: these are saved to create a natural insect repellent used by farmers.

Find out how milkweed is processed and turned into cloth in our interview with Shankar.

Pro: vegan alternative, readily available, no chemicals necessary in the growing and processing, supports farmers.

Con: there is very little capacity at the moment to scale it up, but then that's the beauty of it, right?

Chip[s] Board®

Chip[s] Board® have developed a range of innovative and sustainable circular economy materials using potato waste, known as Parblex™ Plastics [PBX], that are "translucent pure or fibre reinforced bioplastics with incredible surface finish and durability for fashion and interior design". By fashion, it is more about accessories than malleable clothing, but the materials are compatible with injection moulding, 3D printing, milling and other industrial processing techniques so making it applicable to varied product offerings.

Isabel Fletcher made buttons, and Cubitts made eyeglasses [learn more about Cubitts uses unusual materials in our interview with founder Tom Broughton].

Learn more about Chip[s] Board® in our lesson with Rob Nicoll, co-founder, material designer and Chief Product Officer, where we chat about how they take potato peelings and make wonderful durable materials.

Mycelium

The talk about mushrooms is getting louder. On the one hand you have mycelium included in conversations around regeneration, and then on the other, you have discussions about lab-grown fungi for materials (and of course, the psychadelic revolution always going on). It is exceptionally cool either way, and at least with labs you are not disrupting the symbiotic fungi and microbe relationship beneath our feet.

Pro: it is a vegan alternative, it gets people thinking about fungi differently, and genuinely has a lovely texture.

Con: it comes from a lab, we have many hides going to waste due to meat production, and it is not yet commercially available. Sheets are processed in Europe for the high quality chrome-free tanning, but there are surely tanners in the USA? And vegetable tanning gives a stiffer hand feel so limiting applications.

Microbes

Malai produce material from a bacterial culture feeding on sterilised waste coconut water. A cellulose jelly sheet is produced within 14 days, and then after fermentation is complete, this cellulose is enriched with plant fibres like banana stem fibers, gums, and resins to create a durable and flexible biomaterial. The malai material is then formed into sheets in a range of thicknesses and textures or molded into 3D structures, based on the end product.

Pro: Malai works with local coconut processing units to source their waste coconut water, with one small coconut processing unitbeing able to collect 4000 litres of coconut water per day, which can be used to make 320 m² (approximately 380 yd²) of Malai.

Con: Although their material can be made in nearly any shape or size, they are currently limited to supplying 120×80 cm sheets. But this is still wonderful for accessories, jewellery and trims!

We spoke with co-founder Zuzana Gombosova, a material designer from Slovakia, to discover more about how the material is made, what the positive social and environmental impact is and how to get hold of the material itself.

PLA (Polylactic acid)

PLA for fibres comes in the form of corn, sugar beets, wheat and other starch rich products. It can be processed like any other thermoplastic material, so plastic, which is why it is used abundantly now as a "compostable" coffee cup lid or fork. As we rely heavily on polyester for our garments - 52.2% of the global market share of fibre production in 2019 was polyester [Textile Exchange] - polylactic acid fibres can potentially provide an alternative that will offer similar performance capabilities.

Pro: rivals polyester in terms of performance, but with a renewable source (that would need to be sustainably-managed)

Con: it is only biodegradable under anaerobic conditions, so don't think you can put this in your home composter. It is from a food crop, so land use is increasing just to make bioplastics.

We spoke with founder of Nilmore®, Mikuláš Hurta to discover how they are producing a fully circular PLA fibre from a recycled source, so by limiting the environmental damage to land and intense water use from growing such crops.

Of course, we have to mention...

Cactus leather, apple leather and pineapple leather

All of which honestly, we have trouble calling leather. Italy announced a trademark over the term "leather" because it causes confusion. In fact, in our conversation with the director of Leather UK, Kerry Senior, it was mentioned that there is a struggle in calling these alternatives "environmentally-friendly". Though they may come from abundant plants and support communities, they can also be combined with synthetics like polyurethane to create a durable material.

Alice Robinson, designer and material researcher, does signal a place for alternatives in a world where meat consumption has declined and there are no longer spare hides to use. See our lesson from her on Connecting Food, Farming and Fashion.

Fabrics are not food

An issue with materials from food waste, or with raw inputs that could be actual food, is that they are not totally scalable.

...plant-based meat didn’t rise in popularity because people suddenly became more concerned about the planet, their diets, or farm animals. People started eating more of it because it became affordable and accessible, and most importantly, because it actually started tasting good. All of the marketing campaigns in the world can’t change consumer purchasing habits if there are no viable options to switch to. ~ Fashion United 'What Fashion Can Learn From The Veggie Burger Boom', 2 Feb 2021

There are many fashion brands now using these materials quite readily (H&M unsurprisingly is the most recent retailer to take up cactus leather into their "conscious collections"), building up the demand and scale for such materials. This will also drive down the price making it more accessible to independent designers.

However, taking up land that can grow crops to alleviate hunger is not sustainable.

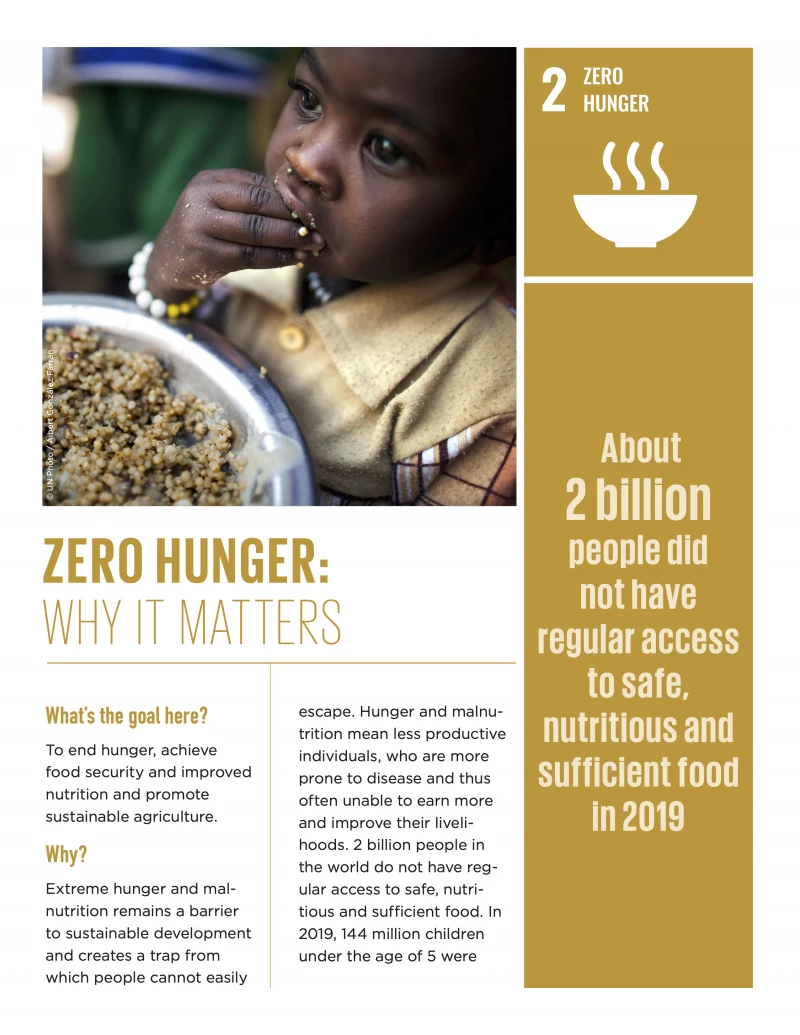

Prior to the impacts of the Covid-19 pandemic being felt across the world, food insecurity was already on the rise. In 2018, 25.9% of the world’s population was affected by moderate or severe food insecurity. Small-scale producers, who comprise 40-85% of all food producers in developing regions, have been hit the hardest by the pandemic.

Regenerative fashion practices to end hunger

The UN's Sustainable Development Goal 2: Zero Hunger, looks at ending hunger, achieve food security and improved nutrition, and promote sustainable agriculture. There are organisations that are building practices to reach these targets. So in our Masterclass on this topic, we spoke to a range of experts to learn about fashion’s impact on food sources, crop health, farming communities and local processing plants, alternative regenerative fibres for fashion fabrics, and the ways designers can support regenerative agriculture practices and a traceable leather industry.

In the Masterclass hear about:

- flax growing to supplement UK agriculture

- leather production misconceptions

- using food waste to create colour

- how cotton farming can increase sustainable food production

- why nettle should be used more for fibre

- what genome editing is - and why bioengineering textiles also fits in this category

- creating new fibre from agricultural waste

Register as a free Member to receive our weekly Masterclass and Inspire emails. Then, upgrade to gain full access to the Masterclasses and individual lessons: you can do so here.

You can also sign up to our newsletter for a bi-monthly fabric rundown.

Additional reading:

Learn about material innovations in the animal-free sector from Material Innovation

'Forget about cotton, we could be making textiles from banana and pineapple' [Offset Warehouse in The Guardian, 2015]