What is pineapple fibre and how do you make textiles from it?

Cultivation of pineapple leaf fibres is an age-old tradition. In the last 20 years or so, it has been revived in order to provide the world with more sustainable fibre options, as well as reigniting the skills of communities. You've probably heard of Piñatex® from Ananas Anam, the leather-look non-woven textile with luxe finishes, used primarily in fashion accessories and shoes by brands such as Po-Zu and Bourgeois Boheme. However, it's not the only way to get pineapple textiles these days.

What is the history of pineapple fibre?

Piña cultivation goes back to Hispanic colonisation of the Philippines, though is grown in other sub-tropical regions too, like Brazil, Hawaii and Indonesia. Being that pineapple trees are grown for their fruit, using the leaves as fibre as well is good commercial sense, especially now that eco-conscious designers are looking to move away from leather and synthetics.

Traditionally, pineapple silk was considered the queen of Philippine fabrics and is considered the fabric of choice of the Philippine elite. Pineapple fibre from the Red Spanish plant is generally used to hand weave such items as the traditional embroidered Philippine formal shirt Barong Tagalog. The Formosa and Cayenne are other pineapple varieties also used for fibre.

Pineapple textiles were popular worldwide, but then came along cheap cotton and consequently ceasing piña textile production. Piña has only been revived in the last 20 years or so due to the demand for alternative natural fibres, re-establishment of local economy and lost craftsmanship, and in fact the revival of the traditional Filipino clothing in order to raise investment in communities.

How is pineapple fibre made?

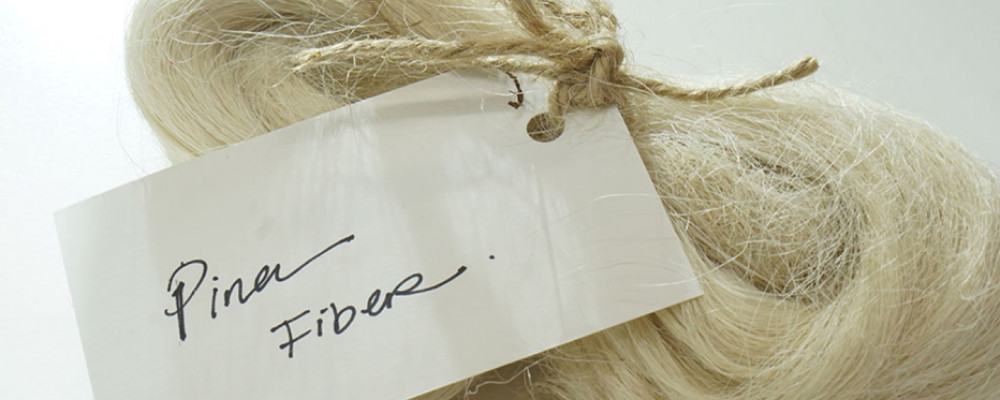

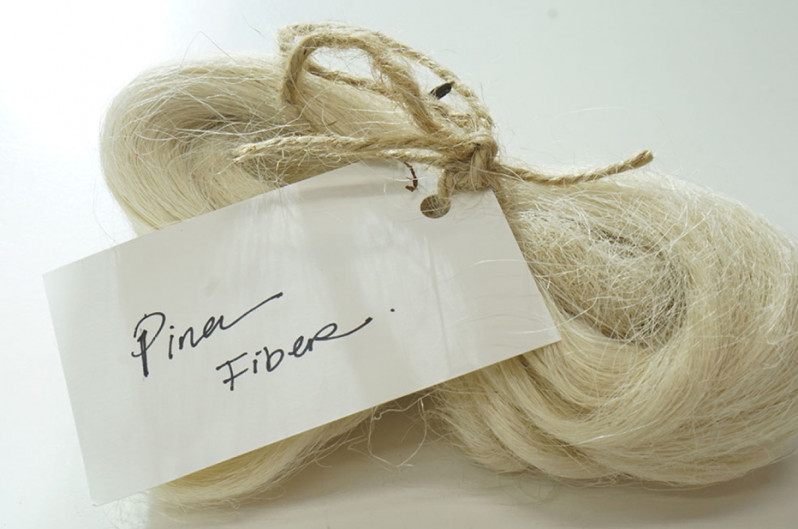

After harvest of the pineapple fruit, the plant leaves are separated from the trunk. The fibres are then manually detached from the leaves by a method of scraping (coconut husks are good for this) known as decortitation. The bundle of cellulosic strands are then washed at a nearby river and hung to dry. After waxing the strands to relieve any entanglements and whipping to release any final plant tissues, the leaf strands are then knotted one by one to create a continuous filament yarn in a similar traditional method as the abaca fibre. A kilo of leaves can provide up to 15-18 pieces of white, creamy lustrous fibre, about 60 cm long each. This is a hand labour-intensive slow process that can often involve 30 people in total.

It's worth noting that, during this process the fibre is split into two qualities: bastos, which is strong and coarse for making household items like rugs, and liniwan, which is very fine so suitable for weaving cloth.

Now that it is ready for weaving, it is up to the skilled artisans to warp and weft the loom as a plain fabric, or with a design.

@OffsetWarehouse explaining how to use sustainable pineapple fibre for fashion garments.

What can pineapple textiles be used for?

Pineapple fibre on its own creates a sheer, stiff material that is light in weight, perfect for use in sub-tropical climates for traditional formal wear and accessories. It is now most famous as Piñatex®, the heavier duty material used as a leather alternative in fashion, footwear and accessories. This is a cradle to cradle material, where the full material stays within its own life cycle - any waste from the production can be used as fertiliser, and they even convert energy into biomas during the decortation (extraction) process. In smaller production facilities, as in just a village, the community will primarily use hand labour rather than machinery, and so while people's energy is wasted, it is overall low impact requiring no electrical energy.

The selection of pineapple textiles at Offset Warehouse are not within a certified cradle-to-cradle system, yet as a natural fibre, can be composted given the right environment. Textiles made using pineapple fibre get softer with each passing generation, and transform into a vintage beige colour, making this a true heirloom material. In contrast to Piñatex®, this more traditional textile can be blended with other natural fibres to create a lustrous luxe hand feel and appearance. Ananas Anam's distinctive chunky non-woven textile is apposite to the sheer lightweight textiles that pineapple fibre can also produce.

Our soft pineapple mulberry silk is ethereal, with a fine weave that would be stunning in bridalwear and couture finishings. In contrast, our structured banana pineapple silk textile is more structured due to the inclusion of abaca (banana), and has a characterful grainy look. This would be an elegant base for embroidery, in millinery and again as couture finishings (think bound buttonholes, Hong Kong seams, place binding and even raw edge trims). Unfortunately, pineapple does deteriorate when reacted with acid so potentially has limitations in clothing, and especially as tableware.

>> Register, and upgrade as a Professional Member of The Sustainable Fashionn Collection for full access to our archive of Masterclasses on ethical fabrics and sustainable fibres. <<

How do I care for my pineapple fabric?

Pineapple fabric are great when merely steamed. This is a low energy solution to freshen up your textiles anyway, but steaming any products made in this textile in your shower room or with a gentle iron, will help relieve any wrinkling or creases. You can wash by hand or even in your machine on a cold delicate wash. You can also dry clean, though we recommend avoiding this due to the chemicals used. As our pineapple textile selection includes blends with banana and silk, you can care for pineapple textiles in a similar way to the other fibres in the blend. Unfortunately as mentioned, pineapple leaf fibres are destroyed by acid, so you must ensure that pineapple fabrics do not come in contact with anything acidic like oranges and lemons. Piñatex® maybe is void of this, due to their finishing process, but we imagine you won't want to eat around this precious textile anyway.

Are these ethical textiles?

At Offset Warehouse ethical and sustainable fabric shop, we only choose fabrics that are good for people and planet. Ethically and environmentally, the resurgence of pineapple for textile use encourages regeneration: both of traditional artisanal skills to employ communities, and of renewable hardy plant fibres. Pineapple is an incredibly labour-intensive textile to produce, requiring both hard graft and skill, though once in place, there can be a continual harvest. Unlike cotton, which requires tilling to re-fertilise the soil, pineapple plants will regrow in the same place. The plants also don’t need any additional land, water or fertilisers to grow.

Pineapple fibres are minimal in impact due to its low water consumption (local rivers and tropical climate), low energy (generally only using people power, though differs between makers), and also as they require no chemicals in growing or fibre production. They also do not need or use genetically modified crops, which ensured the sustainability of farmers’ livelihoods. Dyes are not used, allowing the stunning character of the fibre to sing out, so the textiles are azo-free as well as ensuring no chemicals re-enter the local water supply (because none are used!). Grown close to or even within the small weaving communities, means that transportation is minimal. Pineapple fabric can also be considered a by-product textile that minimises unnecessary waste, due to the leaves being a ‘by-product’ of pineapple fruit cultivation.

Pineapple fibre is technically a by-product of indigenous food systems and are made by hand @OffsetWarehouse

Where can I buy pineapple fabrics?

Our selection of pineapple textiles are woven within small weaving communities on an island in the Southern Philippines, where the pineapple is grown locally. To increase versatility, strength, durability and purpose, these fibres are blended with unusual banana (abaca) fibre from the Philippines, raw silk also cultivated in the Philippines and spun mulberry silk from Canada.

Structured banana pineapple silk is a 25% banana 25% pineapple and 50% raw silk fabric that is soft yet structured, with a wonderfully characterful grain caused by the unique fibre blend. This is perfect for adding structure to a garment, as a stiff base for embroidery, or for super luxe couture trims like bound buttonholes and place binding.

Soft pineapple mulberry silk is a luxurious blend of 50% pineapple 25% raw silk and 25% spun mulberry silk, creating a fabric that is ethereal. Sheer with a creamy colouring, this is so unbelievably special that you really have to appreciate the skill of the craftsmanship from harvest through to the finished woven textile. It is light at only 30gsm, so is very delicate and therefore would be most suited for couture trims, bridal veils, fabric flowers (like at Dior) and very fine embroidery.

If you found this interesting, perhaps you would enjoy receiving our twice-monthly newsletter that brings you updates from the world of sustainable textiles, information on incoming stock - like these beautiful banana fabrics - and carefully selected lessons to increase your knowledge on ethical textiles. Sign up here!

Further reading:

Wikipedia

Textile Today

Philippine Folk Life Museum; for the history of weaving piña textile

The Textile Atlas; a visit to a weaving community with video of weaving

Rurungan Sa Tabod Foundation; Cycle of production

Interested in learning more about how you can use these fabrics in your collection?

The Sustainable Fashion Collective brings you Masterclasses on specific fibre types, design considerations and ethical production. Each Masterclass contains lessons from guest experts, from brands to material innovators.